Precast construction: The way forward

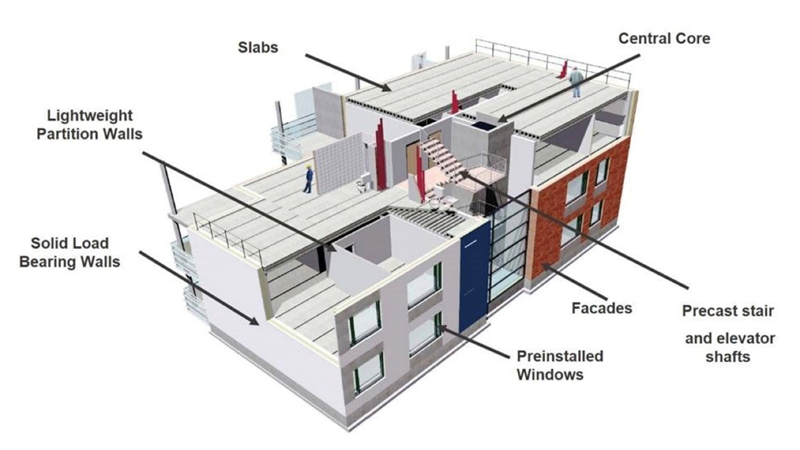

Precast construction is a method which uses prefabricated concrete components in the construction of buildings. In this process, concrete is cast in a reusable platform which is then cured in a controlled setting in a factory and ferried to the construction site where these are put together to form the final desired structure.

It is a highly sophisticated process overseen by structural experts, designed meticulously and executed in a measured environment. Cranes are used to erect the precast elements on site, which are then put together adhering to the minute details prescribed in the structural design, the required rigidity and strength achieved by using grouts and screeds.

Precast construction comes with a multitude of pluses, including reduced construction time, better quality control, increased safety in construction sites, less noise and vibration, much less environmental impact, etc. No wonder, it is now the need of the hour.

Why is precast construction becoming the process of choice?

Rapid expansion and development around the country’s urban areas today demand shorter timelines and reduced construction costs through the use of highly-evolved technologies and methods, ensuring the highest benchmarks in uniformity and quality. Precast construction is now the process of choice for a number of advantages.

# Reduced downtime: The process of cast-in-place concrete is much slower, since it is dependent on the vagaries of the weather and also highly labor-intensive. Reduces time by avoiding green concrete which requires support and curing to gain strength.

During festival season labours availability is a perennial issue which ca be solved.

# Quality maintained

- Factory production in controlled environment

- Uses machines for layout and reduces human error

- Concrete quality good as no delay for transportation of concrete

- Cutting, bending and laying of reinforcement done using machine and gives very nominal error.

# Quick installation: Panels placed in position like cards except they are fixed properly to avoid having a house of cards. Very less support is required since curing is done at the factory and full strength is active there. Hence, the same installation which could take over a month using the cast- in place option, can be done in a day with the precast process in use.

# Durability: Durability depends on curing of concrete. However, ensuring proper curing is very difficult. Precast members are cast and stream-cured (strength gained within 24 hours) in a controlled environment. So, full strength is developed.

# Unmatched performance: All these factors put together ensure a very high level of performance. Precast construction technique guarantees reduced downtime, better quality, rapid installation and maximum durability, making sure the building has a long service life

with minimum hitches. Clearly, precast installations are built to outlast the competition. Cons

- Lots of waterproofing at joints.

- High initial investment.

- Lot of storage area.

- Transportation and handling issues.